Posts, Whitepapers and Special Information

Our unique techologies and Know How need more explanation than a few lines.

Here you can find such special information.

Empty Buildings – how can you keep them safe from Legionella?

Empty buildings, or even buildings partly used, such as barracks, hotels, not fully occupied apartment blocks, are a boon for legionella due to stagnation.

The real key to keeping legionella out of such buildings so they are ready for occupation at a moment’s notice is to keep some movement in the pipelines.

How can that be done without having a maintenance man run around and use water at every fixture every 3 days?

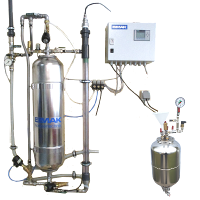

It is called ELMA-LAVAR

Our technology makes water move, back and forth in the system, thereby not adding to the water use, not adding any chemical, but adding turbulence, movement and filtration to keep things clean and moving. It only needs to run for about 30min a day and does not stop water use. It does require the installation of special hygienic expansion vessels and a master station, but then that is all.

Failure to fix a legionella problem?

You got bad legionella tests, the health department were activated.

You have had the assessor come, you got the plumber to change your pipes in accord with the current rules for technology. You even got so called specialists in and installed more equipment such as chemical dosing systems.

After giving out so much money, your facility still fails the legionella test.

The well known rules of the technology are simply not enough to solve the problem alone. Why?

Simply – the stagnation is not being fought the right way.

Our technology helps you fix that mechanically. We put movement in all areas of the water network. We put natural, drinkable minerals in that make it harder for the biofilms to grow. Combined it becomes an unbeatable approach to stop legionella.

This technology can be applied in hospitals, aged care homes and apartment houses.

Don't be scared. Ask us.

Shower ban, rent reduction and bad legionella tests on the third try and nothing is working?

We are looking for an apartment manager or owner organization that is dealing with this problem is seeking a solution and is willing to look outside the box to fix it. Preferably we would like someone in the Cologne-Bonn-Leverkusen area, but we are not too picky, so don't hesitate to call us if your case is from further away. We are seeking a worst case situation as a pilot project for our technology.

Can you run your cooling water system chemical free?

I’ve had it said to me by some that running water without any corrosion protection product is better than with.

Is that true?

Sadly, in the case of many so-called inhibitors on the market yes. I keep coming across products that look like they were developed from boiler water treatment chemicals. They are simply ill suited to the high temperature and cleanliness demands of modern injection molding applications. They do make things worse.

So, the no-chemical approach is better than some products on the market.

But how good is the no chemicals at all solution?

There is such a wide variety of water conditions allowable inside the acceptable parameters for the drinking water ordinance (Trinkw), that water is not the same everywhere. Just take hardness and chloride as examples.

And if you reduce it to pure water – well you are then asking for trouble if you use it alone. It is so hungry for things to dissolve, it will attack the weakest alloy it can find.

If your “pure water” comes from reverse osmosis, that is not pure. Put a pH meter on it and see for yourself.

So, if you can afford the loss of materials in your form – go for it. Your water treatment will be close to zero.

Believe what you want and pay the price for ignoring the facts of chemistry and physics.

Changed chemical supplier and now there is rust and chaos?

You have changed your chemical supplier and now there is rust and chaos?

Purchasers are trained to get the cheapest price. Quite often it also means the cheapest product in water treatment.

This can be devastating to high quality manufacturing requiring only the best quality cooling water.

Without the right technical input, wrong decisions can lead to chemical chaos, that is only detected months after the cheapest product has been implemented. Changing supplier multiple times can make things worse.

Not all chemicals are created equal.

Who in your company has the most say? The ones making the necessary technical decisions to produce the products your company makes a profit on, or those who just see numbers.

How to solve it? You cannot change upper management from below, but you can quantify your costs.

Quantify just how much more repairs are costing with real figures. Extrapolate how much worse this will be if you continue down the discounter path in 1 year, 2 years. Extrapolate the lost production in monetary terms and with those figures in hand, demand quality water treatment.

Need help – just ask.

Cooling water for the Plastics Industry: Why you need ultrafiltration!

Spoiler alert….you don’t need ultrafiltration. There are some industries that need it, but injection molding is normally one that does not need it. It is plain and simple overkill. Why?

It is being used to mask the problem of incorrect corrosion protection. A very common corrosion inhibitor is causing what we call the “Fanta Effect” – that is orange coloured water that can barely be filtered. Basically, the corrosion inhibitor allows rust half way, stops it from becoming black/brown rust, but does not stop it eating away at the substance of your forms, machines, and pipes.

If you use ultrafiltration, you can filter this junk out. But you are just masking a serious corrosion problem.

If you have fallen for the ultrafiltration hype, take a sample of your water before your filter, or turn it off for a while. What about the filter elements you had to replace up till now? Are they orange? What is the colour of the water? How good is your corrosion protection? Are you seeing your investment in machines and forms erode and slowly build up on the expensive filter elements you have to keep replacing.

What is the solution? Stop the “Fanta Effect” with corrosion protection that really works. E.g. EMC KS20.

Low Capital Cost Cooling water Systems – Filled with sludge!

So your purchasing and management approved the lowest bidder to supply your cooling water system. Congratulations! Your company kept its investment budget low.

Two years down the road and now the supplier does not want to help you with your problem. There is sludge in the water. You keep having to clean things out. You are not sure if its rust or oil or what, but it upsets your production and the down time is hurting. Now the management are on your back about the lost production.

What can you do?

Sorry your company bought the wrong equipment! The money is gone. We can’t change that for you. We can help you deal with the symptoms of a short-sighted decision by management.

The problem needs to be attacked at the source, rather than the symptoms.

The sources are:

- Open circuits allowing air and bacteria to enter the cooling water

- Poor choices of corrosion protection chemicals

- Lack of or the wrong kind of filtration

- The wrong kind of water treatment

To fix it – you can’t do any of this by half. For example, flushing the system clean might be a temporary help, but you give the same causes a fresh start – new metal surfaces to corrode, new water for bacteria to colonize, fresh chemicals for them to eat. Even just filtering will do some good, but if the chemicals aren’t right you can easily create a super bacteria brood on you filter, ready to make more corrosion inducing acids.

Tell us about your system, talk to us. Every case has its specialties. We have fixed many of these systems using our water treatment chemicals together with our specialist devices. We treat the cause, not the symptom.

Oil Contamination in Cooling Water – What can you do?

In systems where cooling water and hydraulic oil are in close proximity, oil contamination can happen.

Prevention is always the best cure. Good form design, clean form changes, are all important.

But then it happens and the system is full of this awful mess. Everything gets coated in a white grey goo.

Three steps help:

- Wash it out with the right chemicals

- Filter it out with the right media

- Keep the system bacteria free

We supply a chemical and a technique to do the wash out step without causing a stop to production.

In severe cases we can also assist in flushing with pigs and shock cleaning.

In cases with limited contamination, or ones just flushed, two stage filtration helps. Our EMM Superpor media is superior to quarz and glass based media, as it has extra absorption capacity for oil particles. Micro filtration using lipophyllic Cartridges works well as the next stage.

Keeping the system bacteria free is important. Small amounts of oil offer bacteria food to grow on. Our water treatment chemicals keep the balance to stop corrosion and bacterial activity.

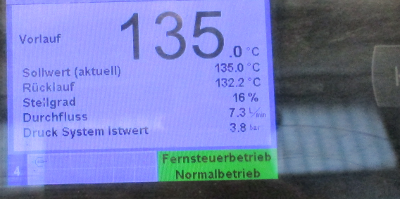

Why does everything break down in high temperature control?

You have "immunized" the cooling water system. So far no big problems.

Now your production uses temperature control units operating above 100°C, and all sorts of strange corrosion damage is occurring.

What can you do?

1. Get the water treatment right

2. Manage the filling and pressure correctly.

3. Audit your choice of materials

Water over 100°C is far more aggressive. Acidic elements work stronger. Most corrosion inhibitors break down. Anything that can cause scale will cause scale. Cavitation risk is dramatically higher.

Material durability: some alloys, seals and ceramics begin to react with water.

Solution 1 – Water treatment:

Our corrosion protection chemicals are stable above 100°C. They also keep things alkaline, stopping the acidic attack. We also help you to use water that has nothing that can produce scale.

Solution 2: Filling:

Ideally if you treat your entire cooling water to the same standard, and degass it sufficiently, then the fill water used on your temperature control units will be optimized as well. If this is not possible, we have “island” solutions. However, in some complex cases this requires consultation as not all production processes run the same.

Additionally holding pressure in conditions where water “wants” to evaporate to steam require some additional measures we can help with.

In many cases, temperature control unit manufacturers only have limited (mostly electronic) means to control these physical phenomena. A little more technology from us may be needed.

Solution 3: Audit your materials

Consult with us. Let us know what alloys, seals and couplings you are using. It can be that specialist components are not suited to the temperatures and pressures and strange behaviors of “normal salts”.

High temperature-controlled molding is achievable. Let us work with you to fix the water side of the equation.

Do you really need an oxygen binder in your cooling water?

Everyone knows that oxygen is involved in corrosion. This basic understanding has led to a lot of products being developed that scavenge and bind oxygen in cooling water.

Like all technologies there are applications that really do need it. But is it necessary for cooling in the plastics industry?

Often it is the worst thing you can do. All too often these chemicals are placed in open systems, full of oxygen and the high demand and high levels of bacterial contamination turn these chemicals into acids and acid like compounds. Rust increases, you add more product thinking you are doing the right thing and it just gets worse.

In hermetic systems it happens a little slower, but the same mechanisms apply. Really only in things like space technology do you get water without oxygen getting in. And then if you use this water full of scavenger byproducts above 100°C – expect chaos. And remember, even hermetic systems let air in, they are not space travel sealed.

So, if its all bad, what do you do instead?

Use corrosion protection products that handle the oxygen.

Degass, reduce the % of oxygen and carbon dioxide dissolved in your cooling water.

Keep the water clean

Simple isn't it?

Too much gas!

Are you using reverse osmosis. Great, it has a lot of advantages.

Does what you are using it for have corrosion issues? Does it have potential cavitation issues?

RO water is not pure water, its salt free and that is great.

It is not gas free.

In fact, the RO process makes it disproportionately loaded with carbon dioxide. This makes it acidic. Put that in contact with anything containing metal and the hungry acidic water will do something bad.

For some applications this is not an issue. However, if you are using RO water for cooling water make-up, or boiler water or autoclave feed water you need to remove those gases to reduce risks to your process.

If you add chemicals later, you may be adding too much as a lot is needed to overcome the CO2. If you are fighting oxygen too, then you need something to make this less of an uphill battle.

One effective way to get the CO2 down, along with other gases like oxygen, is to use high-rate vacuum degassing. The EG100 vacumm degasser is the perfect starting point. Custom solutions using the same principle can be made for larger systems.

Cavitation or Corrosion? Can you tell the difference?

"It must be corrosion - shoot the supplier!"

Its amazing how often damage to tools is blamed on corrosion. True, you go for bad inhibitors, bad water treatment, disaster is assured.

However, we encounter quite often that the cause of form damage has little to do with the water quality, but rather the physics.

Cavitation can cause destruction of metal, much in the way a water jet cutter works, but with more destructive power, on a microscopic scale.

We can help you to identify such problems correctly and to solve them.

Just a question for thought – if it is corrosion, then why are the damaged areas so clean? Do you need to rethink what you are doing with your water?

Are cooling towers really so evil?

Anxiety seems to drive too many business and process decisions in Germany.

I have been seeing it happen in cooling towers. The VDI2047 and associated rules are welcome from a public health perspective. For those with high heat loads such as the food industry, compliance is a must, as they cannot afford alternative heat rejection methods

For small to middle sized producers, particularly those working in plastic, I have seen all too many get scared and go to less energy efficient methods such as compression cooling. Why?

Anxiety.

Cooling towers have a dirty reputation. It is totally unwarranted – it is so easy to keep them as clean as a swimming pool. But the potential of a nasty letter from a regulatory authority seems to overshadow all that.The bureaucratic headaches of regular tests for legionella and finally spending some money on technology have led many to run away from cooling towers like avoiding the plague.

No shortage of companies wanting to sell compression chillers. They do work well.

How many though made these decisions looking at the total cost of ownership of one technology over the other? How many took into consideration the energy costs?

Chillers do not usually win here, as it is hard when the coefficient of performance for evaporative cooling is usually 20 times better or more than compression chilling, even when you doctor the numbers to make the chillers look better.

I’d love to see someone come forward and say – we did the math and compression cooling is saving us money – look at our power bill!

As said on a popular science fiction show – “You cannot change the laws of physics!”

Anyone got those kind of figures?

Sind nahezu reine Wassersysteme korrosionssicher? Ist Sauerstoff der Bösewicht oder das Ungeheuer?

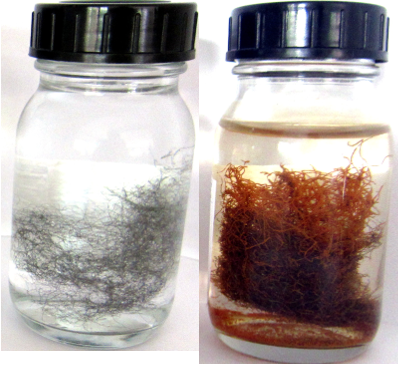

Probieren Sie Folgendes aus: Kaufen Sie destilliertes Wasser. Kochen Sie es, um alle Gase zu entfernen. Gießen Sie es in ein Glas und geben Sie etwas Stahlwolle hinein. Beobachten Sie es in den nächsten Tagen und prüfen Sie, ob es rostet. Haben Sie den gesamten Sauerstoff entfernt? War das möglich? Ist es nun korrosionssicher? Wie lange hat es gedauert bis es rostet?

Die VDI 6044 empfiehlt viele Verfahren, wie z. B. die Reduzierung der Salz- und Gaskonzentrationen. Zu diesem grundlegenden Punkt haben wir nichts zu beanstanden. Wie dies jedoch von einigen in der Branche umgesetzt wird, lässt uns nur den Kopf schütteln.

Ionenaustausch zur Entfernung von Sauerstoff - sogn. Sauerstoffzerrpatronen: Die Methode funktioniert chemisch. Als Endverbraucher wissen Sie jedoch nicht, wann das Gerät keine Kapazität mehr hat. Bei jedem Sauerstofftest wird die Probe mit Sauerstoff kontaminiert, was zu dem Ergebnis führt, dass sich „Sauerstoff“ im System befindet, sodass Ihr Lieferant sagen kann: „Der Harz ist abgelaufen, Sie brauchen Neues!“ Das ist großartig für ihn, da jeder Besuch mehr Geld für ihn bedeutet.

Es könnte aber auch wahr sein, da Sie nicht verhindern können, dass Sauerstoff in hermetische Kühlwasser-Systeme eindringt. Hanf, Gummimembranen und Pumpendichtungen können Sauerstoff ins Wasser lassen.

Wenn Sie nicht zur ESA oder NASA gehören, vergessen Sie es, Ihr System zu 100 % abdichten zu wollen.

Was passiert, wenn Ihr Sauerstoffzerrpatrone-Harz „undicht“ ist? In der Regel handelt es sich dabei um gefährliche Sulfid- und Sulfit-Ionen. Denken Sie an Batteriesäure!

Darüber hinaus werden durch die Ionenaustausch-Sauerstoffentfernung CO2, N2 und andere Gase nicht entfernt. Die VDI 6044 erwähnt N2 Blasen als Erosionsverusacher. Niedrig N2 Werte sind nur mit Entgasung zu erriechen.

Die Vollentsalzung ist wichtig. Wir empfehlen sie immer. Das resultierende Wasser ist jedoch so mineralstoffarm, dass es Ihre Metalle angreift, selbst wenn kein Sauerstoff vorhanden ist.

Sie müssen noch etwas mehr tun. Sie müssen in der Lage sein, ihre Metalloberflächen sofort zu passivieren, auch wenn Ihr Sauerstoffgehalt niedrig ist und das heißt: Verwendung von geeignete Korrosionsschutzmittel.

Die Wissenschaft kennt verschiedene Potenziale für die Auswaschung von Metallen im Wasser. Kupfer und Blei werden häufig von Trinkwasserspezialisten verwendet, aber auch Zink und Eisen spielen eine Rolle. In allen Fällen haben diese Metalle das höchste Potenzial, sich im Wasser aufzulösen, wenn das Wasser in seinem reinsten Zustand ist. Selbst in Abwesenheit von Sauerstoff kann Wasser Metallhydroxid-Korrosionsprodukte bilden. Dies ist ein Punkt, an dem die Grenzen der Empfehlungen der VDI 6044 deutlich werden die auch in andere Regelwerke und Wissenschaftlichen Quellen findbar sind. Reines Wasser ist gefährlich für Metalle. Sie benötigen mehr Schutz als nur die Entfernung von Sauerstoff!

Warum verkaufen wir keine Sauerstoffzerrpatronen?

Wir verstehen sie sehr gut. Mann kann damit jede Menge Geld verdienen!

Die einfache Antwort lautet: Wir glauben die Werbesprüche nicht, dass sie gut genug funktionieren, und wir erzielen ohne sie bessere Ergebnisse. Wir verkaufen nur was wir garantieren können.

Die meisten harzbasierten SO3->SO4-Systeme sind nicht garantiert Ion-Leck frei. Das bedeutet, dass SO3 und SO4 versehentlich in das System gelangen können. Dabei handelt es sich um Ionen, die selbst in sehr geringen Konzentrationen schwere Korrosion verursachen.

Die Reaktionszeit dieses Prozesses zur Bindung von Sauerstoff ist langsamer als die Reaktion von Sauerstoff mit Metallen wie Eisen und Kupfer (siehe FW 510 6.5.4.). Das bedeutet, dass Ihr Metall korrodiert, bevor der Sauerstoff in der Patrone gebunden wurde. Die Kühlwassertemperaturen sind oft niedrig, was diesen Prozess noch weiter verlangsamt.

Sobald anaerobe Bedingungen herrschen, finden die schlimmsten korrosionsverursachenden Bakterien die notwendigen Voraussetzungen, um aus sehr geringen Konzentrationen von Schwefelverbindungen wie SO3, SO4 und H2S korrosive Säuren zu produzieren.

- Mit dieser Methode lassen sich vollständige Passivierungsschichten nicht schnell genug herstellen. Die Ionenwanderung (nicht unbedingt Rost) kann nicht verhindert werden. Die Oxidation findet weiterhin statt, auch wenn kein oder wenig Sauerstoff vorhanden ist.

- Teilstromsysteme werden häufig mit Entionisierungsfiltern kombiniert. Warum wenn man schon VE-Wasser als Nachfüllwasser verwendet hat? Um sowohl die aus dem Sauerstoffzerrpatrone austretenden Schwefelverbindungen als auch die aus den Materialien austretenden Metallionen aufzufangen. Das bedeutet, dass die Probleme durch die Beseitigung der von ihnen verursachten Verschmutzungen verdeckt werden!

- Die Betriebskosten für den regelmäßigen Austausch der Harze betragen bis zum Zwölffachen der Kosten anderer Technologien. (Laut Google KI – die Durschnitts-Kosten von Sauerstoffzehrpatronenbetrieb sind ca. 600 EUR/Monat).

- Es gibt z.Z. keine praktikabel kostengünstige Möglichkeit, zu testen, ob ein Sauerstoffzerrpatrone den Sauerstoff entfernt hat oder die Materialien korrodiert sind. Ebenso gibt es keine kostengünstige Möglichkeit, festzustellen, ob der Sauerstoffzerrpatrone aufgebraucht ist! (Siehe dazu VDI 6044 5.1.8 Anmerkung 1)

Wir bevorzugen die Kombination unserer Nebenstrom-Vakuumentgasung, mit der der Gehalt an gelöstem Gas um bis zu 92 % der ursprünglichen NKG-Werte reduziert werden kann, um eine sehr geringe Konzentration an Sauerstoff und anderen Gasen zu erzielen. Anschließend nutzen wir die geringe Sauerstoffkonzentration mit schnell wirkenden anodischen Inhibitoren, um „blitzschnell“ eine Passivierungsschicht zu erzeugen oder sogar zu reparieren, wodurch verhindert wird, dass unkontrollierte Metallionen ins Wasser gelangen. Unsere praktischen Erfahrungen zeigen, dass dies funktioniert und die Betriebskosten deutlich niedriger sind als bei der Sauerstoffzerrung.